- Home

- Blog

- Explore treatments

- Mastering digital impressions ...

Mastering digital impressions for dentures: where to start?

Intraoral scanning can revolutionize your practice, especially now that scanning for digital denture workflows has evolved to where it is today. Some denturists and clinicians will jump fully into this ever-developing field. Others may decide to only replace key steps on the treatment journey.

Team of TRIOS training experts

As pioneers in the field of digital dentures, our team of learning experts have onboarded and trained clinic teams since scanners first appeared on the scene decades ago. With this blog post, we aim to make your journey into digital dentures a bit clearer and more predictable. So let’s take a look.

First, I will introduce you to the realm of digital full dentures. Then, I will dive into what is required to digitize traditional denture workflows with digital denture impressions. And lastly, I will share my perspective on why digital removable prosthetics have become one of the most interesting topics in restorative dentistry today.

Where it started in 2014: the first CAD workflow for digital denture design

Safe to say that -back in 2014- it was very early days for CAD/CAM dentistry in cemented and implant prosthetics. This was also true of full dentures. In other words, the industry was not ready for digital dentures. Our dental CAD/CAM solution at the time enabled practitioners to design simple full dentures with a rudimentary workflow on scanned gypsum models, wax rims and impressions with the help of the lab scanner portfolio. The Removable Partial Denture module also existed at this time.

Over these past 9 years, this ‘simple package’ has evolved into a full-fledged dental design software that caters to most digital full and partial denture treatments. The starting point for each of these can either be a digitized impression, a gypsum model and of course an intraoral scan.

What to do when taking digital dental impressions for dentures

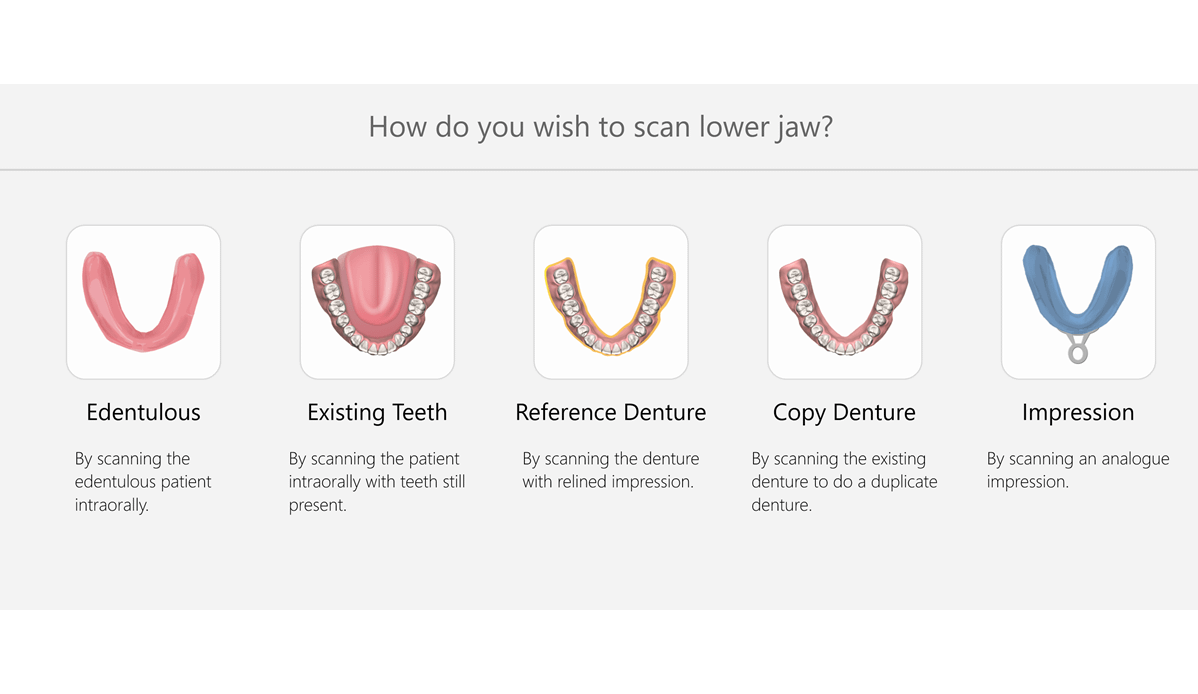

Depending on your methodology, you can start your denture treatment from a direct mucostatic scan, existing teeth, an existing denture or a functional impression in the clinic. So what does it take to use your TRIOS intraoral scanner to scan the edentulous patient, a reference denture or the actual functional impression you have taken? Let’s dive in.

Scanning edentulous patients

Reference dentures protocol

Learn to scan reference dentures or edentulous with these two ebooks, containing detailed protocols.

Reference dentures training

A digital reference denture workflow with a try-in reduces patient visits from the conventional five to a possible three. Dive deeper with our reference dentures training course that covers the entire process, from scanning wash impressions and establishing OVD to using a try-in to test fit, form and function.

We will show the initial design steps and look at making modification to the design after communicating changes with the clinic.

Communicating with your lab

If you decide to send the denture case to your lab, your denture workflow starts with the order form. This form needs to reflect as precisely as possible what you are about to order from the dental laboratory.

This training video shows you how to communicate all these delivery, work type, material specifics to your lab, and add text and images to your case before you send it over to your lab. It also shows you how the case gets accepted by the lab.

Manufacturing of digital dentures

For manufacturing of dentures, the practice or lab will be using two main manufacturing techniques in digital full dentures are milling and 3D printing.

The initial investment, efficiency, cost of material, production time and material properties are different for both of these techniques. When it comes to selecting the technique for your dentures, it’s common to mix manufacturing techniques. This video shows you how this is done.

Getting started with digital denture impressions

Going digital in removable prosthetics does not necessarily mean that everything has to change overnight. Nor does it mean abandoning the best practices from analogue techniques, such as functional impressions or the try-in stage.

But when done correctly, digital techniques may help you complete patient treatments with less visits and more predictability.

No matter how you wish to adopt digital denture solutions into your treatments and processes, there are true benefits in exploring this rapidly developing field.

- Home

- Blog

- Explore treatments

- Mastering digital impressions ...

Take our dentures fundamentals course to get introduced to design software, materials, denture types and production machines.