3 step guide to making model free crowns with Dental System™

In the last 3Shape Digital Trends Newsletter (August 2014), lab owner Sune Schmidt told his story about how he created a successful business model by offering model free crowns to his dentists. The crowns are dubbed model-free because they do not require the lab to make a model of the patient's mouth in order to test and fit the CAM manufactured crowns. Market interest for model-free crowns is growing every day and in this issue, Sune Schmidt reveals how he makes them.

Schmidt Dental Lab is a relatively small family business based in Horsens, Denmark. This past September the lab shipped 211 model free crowns to dentists in Denmark. This broke their previous record of 160 model free crowns sent in August. The 211 manufactured crowns mark an increase in production per month of over 1200% year on year for the dental lab. The lab is also growing its client base due to more dentists hearing about the product.

We asked Sune: So how do you actually make your model free crowns?

“Generally speaking, its the accuracy of the TRIOS digital impression, together with well-defined and carefully-tested design and milling parameters that make it possible to produce perfectly fitting crowns without models,” says Sune Schmidt.

In the following, Sune takes us through the basic steps for producing model free crowns in Dental System™ using TRIOS scans.

The model-free crown workflow – by Sune Schmidt

Making model free crowns can be roughly divided into 3 main steps:

- Design the crown, including all contact points and articulation for correct dynamic occlusion.

- Apply your milling strategy settings, cement gap space, and mill the crown

- Perform manual post-processing - staining and glazing for esthetics

Allocate time for testing in collaboration with your dentist

When you start working model-free, you and your dentist will need to test the crowns during the first period. Testing is the key to achieving an efficient and reliable model-free production. This is how you, once and for all, accurately tune your model free crowns interface parameters in the software to match your specific milling machine and material. I will speak more about testing under the workflow step: Set the die interface and cement-gap parameters.

1. Design the crown

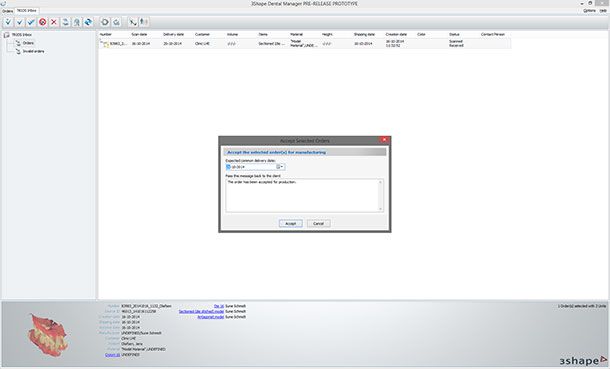

1.1 Receive the scan in your InBox

Set the delivery date so the dentist knows when he will get it back. When working model-free this will potentially be faster.

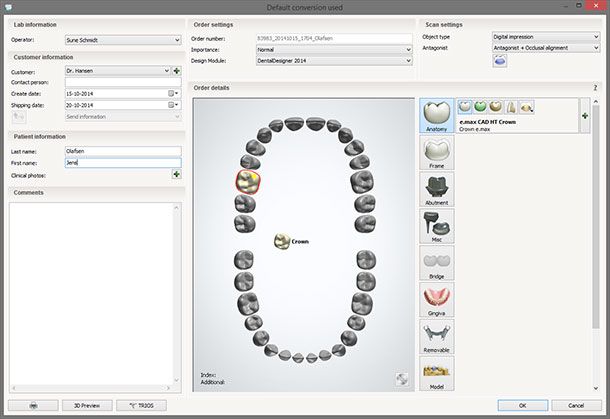

1.2 Create the order

Here you select the material of the crown. Make sure that you do not select the Model option as we are going to produce a crown without a model and do not need to initiate the Model Builder in Dental System™.

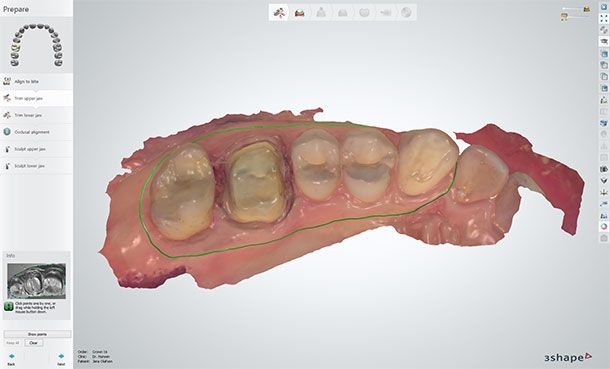

1.3 Prepare the scan before design - Trim the scan

The dentist may have trimmed the scan before sending the digital impression to your lab. However, it is important that you check the scan for excess material and remove any at this stage. I trim the model as much as I can and many dentists expect me to handle this part. Excess material in the scan can interfere with the bite registration and affect the accuracy of Virtual Articulation when you check the crown later on in the software.

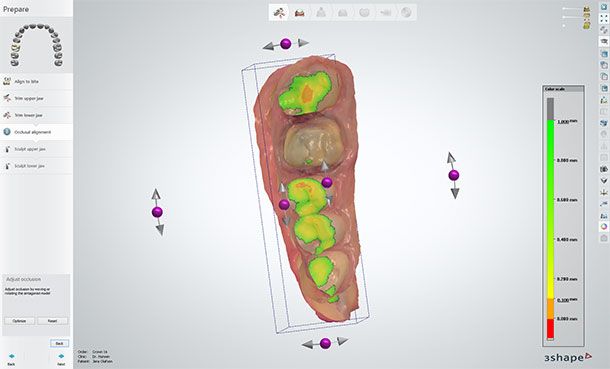

1.4 Check the static occlusion of the bite scan

The dentist will often have controlled static occlusion himself in his TRIOS system. However, it should be verified in the lab before designing because you will not have a model to control static occlusion later on. Realign the bite if needed.

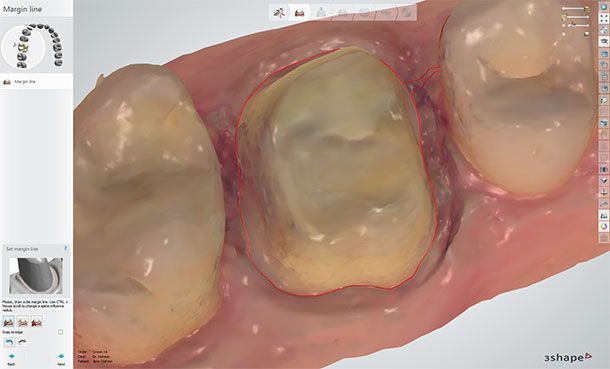

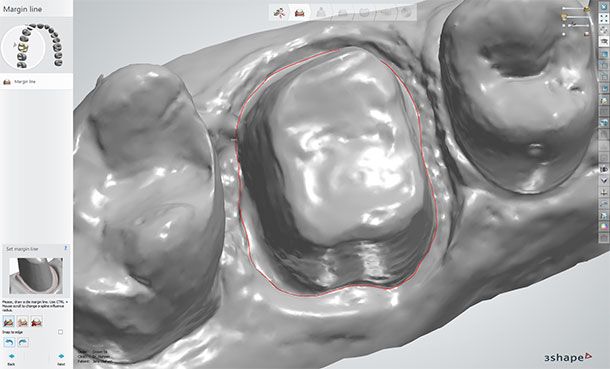

1.5 Set Margins

It's a good idea to combine viewing the impression with and without colors when setting the margin line. The two separate views will bring out different aspects of the margin area and help you determine the exact margin line position. You can also use HD photos if the dentist included these with the digital impression. The 2014 version of TRIOS software makes it easier than ever to see margin details. Here again, the dentist may have set a margin line, but its good practice for the lab to control this before designing and milling the crown.

1.6 Control the Insertion direction

I rely on the automatic Insertion Direction option in Dental System™ to set the initial direction, and then I control it manually.

1.7 Set your die interface and cement-gap parameters

You will need to tune the cement-gap parameters to your specific milling machine and material. This is the key step when setting up an efficient model-free production workflow, and you should give it the effort and time it deserves.

The only reliable way to find the perfect setting is to run a series of tests. You can start by using models to get a rough idea of the values. But the real testing is done in collaboration with the dentist who will test the fit of your crowns on the patient.

In practical terms, this means that during the testing phase, you should design and mill at least 3 versions of the crown with varying cement-gap settings. Then you will send all of these crowns to the dentist who tests them on the patient. The dentist then reports back which of the crowns fits best. Repeat this process on more cases and use the data you collect to determine the perfect cement-gap for your model free crowns.

Once you have found your perfect cement-gap-setting and production parameters, you can rely on these for every case when milling model free crowns on the same machine and in the same material. Naturally, you will need to test again if you invest in a new machine or use another material.

1. 7 Design the crown

Design the crown as always, or use the Auto Crown feature depending on your specific case.

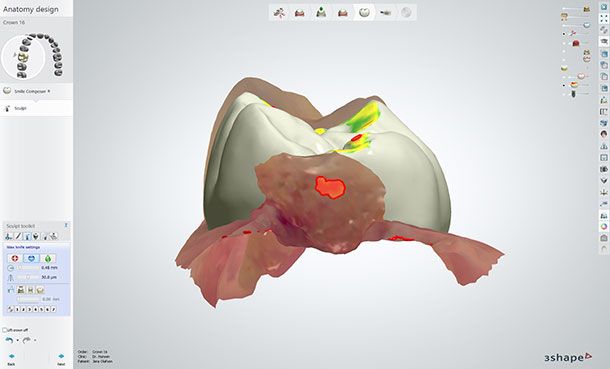

1.7 Design and control your contact points

Design and control the crown in relation to your mesial and distal contact points. You can use the Auto Placement tool to get an initial suggestion, and Dental Systems™ sculpt tools to refine. The scissor tool lets you view the tooth surface from the inside to quickly see where and how much material will exceed the contact point. You can also use the distance map to evaluate your mesial and distal contact points.

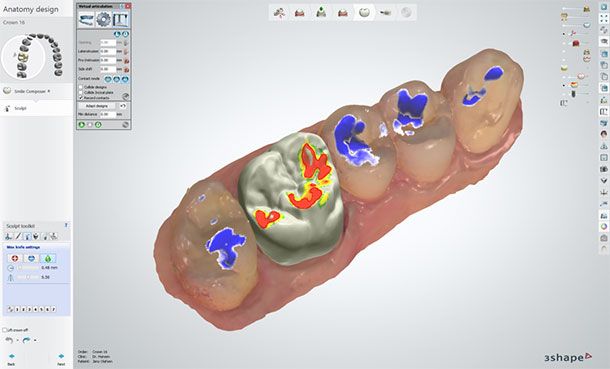

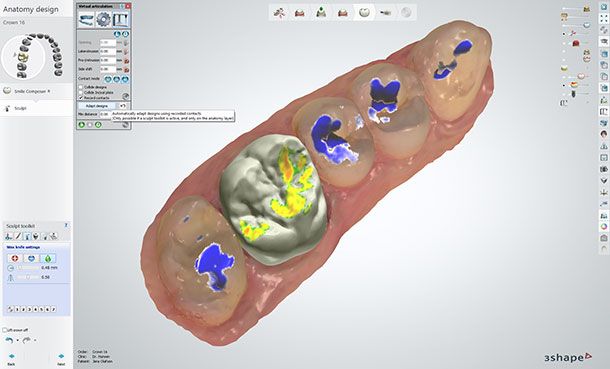

1.8 Apply Dynamic Virtual Articulation

Since we are working without a model, you must always control dynamic occlusion using the software Virtual Articulator. You will not have a model to place in a physical articulator.

Check dynamic occlusion in the software

1.9 Virtual Articulation – Adapt Design and check contact points

Press the “Adapt Design” button to remove material that obstructs smooth dynamic occlusion. Naturally, you end with checking your occlusal contact points.

2.Mill the crown

During testing as described in step 1.7, you determined your milling strategies and parameters for all model free crowns milled on the same machine and in the same material. Select the optimal milling parameters with regard to speed versus detail. Your presets will enable high milling productivity with model-free crowns.

Beware that a worn drill can affect results making your presets inaccurate. I recommend that you define clear rules (intervals, number of crowns) for when you should change the drill in order to ensure consistency.

If needed, you can mill your model free crowns externally if you are not yet ready to invest in more machines. If you do, you and your milling service will need to run tests in collaboration with the dentist, in order to get the right milling strategies and cement gap parameters.

3. Post-process the crown

Stain and glaze the single-piece model-free crown as instructed by the material provider. If I don't need to stain the crown, I can crystalize and glaze in the same program to save time.